Plastic Granules Making Machine Manufacturers in Ahmedabad, Gujarat

50-300 kg/hr

Production Capacity

65-125 mm

Screw Size Range

ISO 9001:2015

Quality Certified

28+ Years

Manufacturing Experience

Plastic Granules Making Machine Manufacturers in Ahmedabad, Gujarat

Mahek Roto Mech is a leading Plastic Granules Making Machine Manufacturer in Ahmedabad, Gujarat specializing in high-quality plastic recycling and pelletizing machinery. Our machines work on the principle of plastic extrusion process, enabling high-volume manufacturing for granules, tubes, sheets, and lumps production.

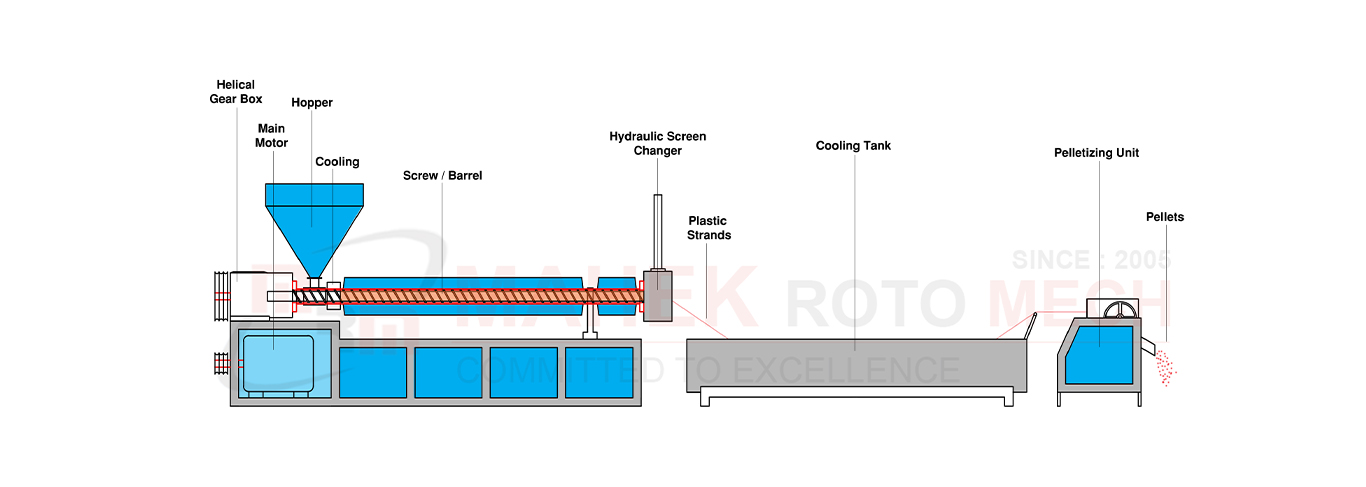

How Plastic Granules Making Machine Works

The process begins with plastic flakes being placed into the hopper. A hopper magnet prevents metallic particles from entering the barrel. The raw material gravity-feeds through the feed throat onto the rotating screw. Barrel heaters melt the plastic as it moves forward. The molten plastic is filtered through a hydraulic screen changer and converted into strands, which are cooled in a stainless steel water tank before being pelletized into finished granules.

Technical Specifications

| Model Parameter | Specifications |

|---|---|

| Production Capacity | 50 kg/hr to 300 kg/hr |

| Screw Size Range | 65 mm to 125 mm |

| Material Compatibility | LLDPE, HDPE, LDPE, PP, HM, PVC, ABS & HIPS |

| Heating System | Digital pyrocontrol panel with multiple zones |

| Drive System | AC Motor with heavy duty helical gear box |

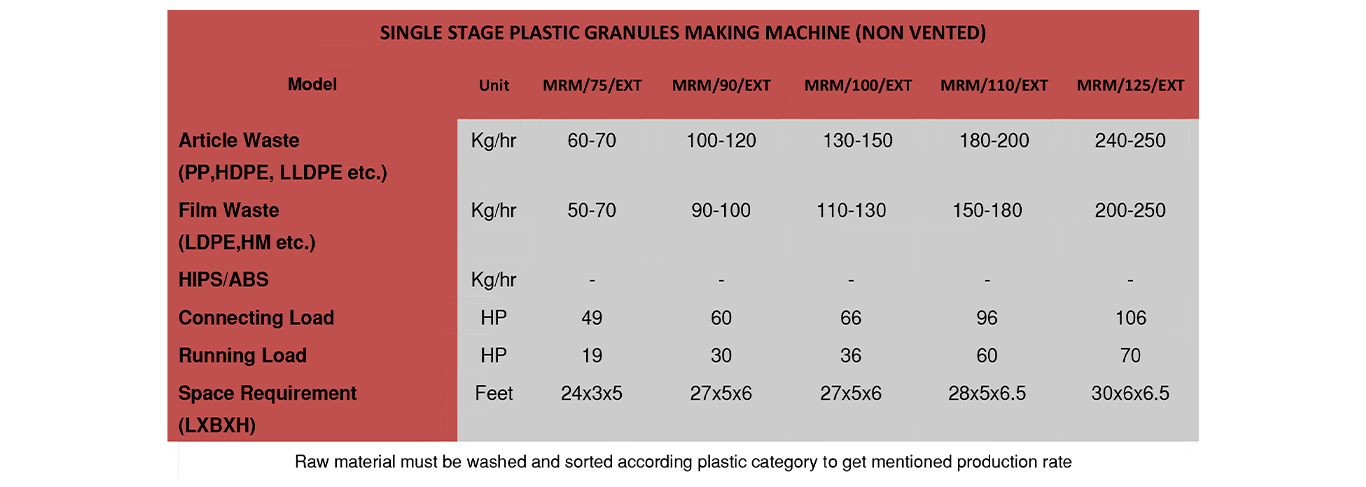

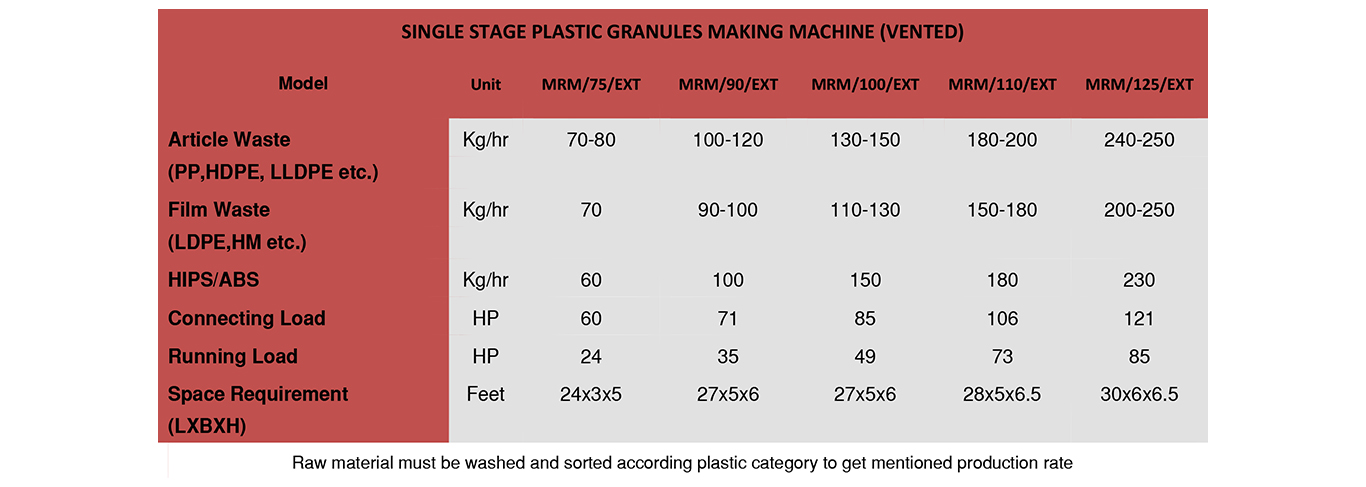

Model Range & Production Capacity

We offer various models classified by production rate, with screw sizes ranging from 65 mm to 125 mm extruder models. Production capacity ranges from 50 kg/hr to 300 kg/hr to suit different business requirements.

Salient Features Premium Quality

- Screw & barrel made of EN41-B mild steel, nitride and honing finished for quality production & longer durable life

- Optional: Tungsten carbide coated screw & barrel available for high production machines

- Screw design optimized for reprocessing & coloring application of various plastics

- Barrel divided into heating zones for accurate temperature control

- Digital pyrocontrol panel for faster heating & energy saving

- High efficient hopper magnet to detect and restrict ferrous materials

- Hydraulic screen changer to filter molten plastic from dust or particles

- Stainless steel cooling tank with guide rollers

- Pelletizing unit with carbide tips moving blades driven by AC motor

Optional Features Customizable

- Tungsten carbide coated screw & barrel for high RPM machines

- AC drives from reputed brands for precise motor speed control

- Pressure transducer with buzzer system for hydraulic screen changer

- Automatic hopper loader to reduce labor requirements

- Air knife for moisture-free pellets output

- Forced feeder for low density raw material

- Barrel vent for engineering grade materials

- PLC based HMI control panel with touch screen display

- Vibro shifter to separate rejections and finished granules

Machine Layout & Specifications

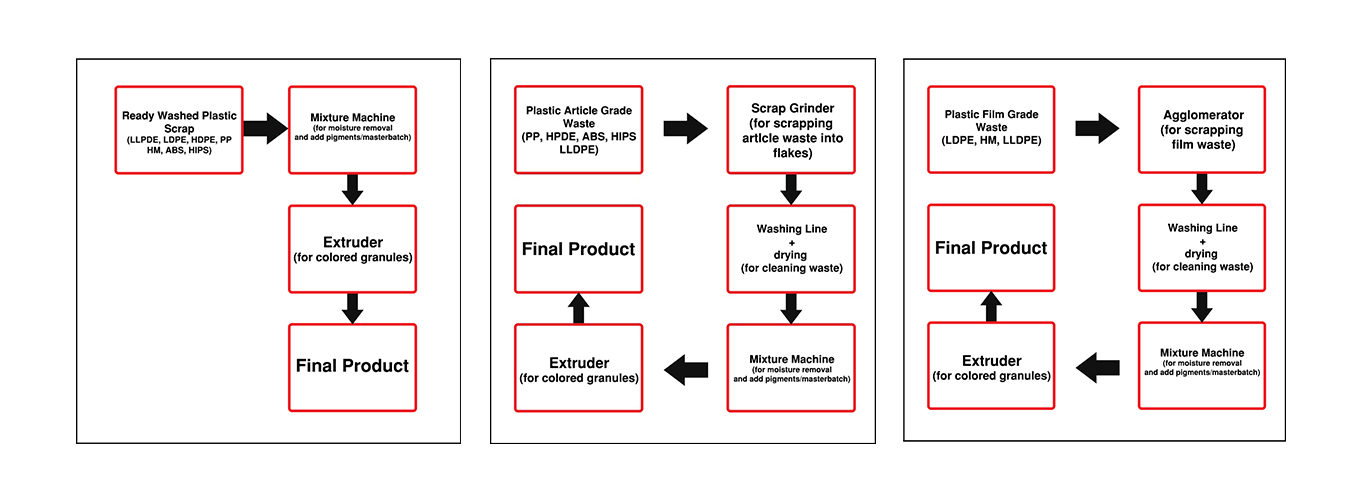

Plastic Granules Making Process Flow

Customer Videos & Testimonials

Ready to Start Your Plastic Recycling Business?

Get the best Plastic Granules Making Machine from trusted manufacturers in Ahmedabad, Gujarat