Mother Baby Plastic Recycling Machine Manufacturers in Ahmedabad, Gujarat

100-500 kg/hr

Production Capacity

Double Stage

Two Extruder System

ISO 9001:2015

Quality Certified

Moisture Free

Complete Moisture Removal

Advantages of Double Stage Mother Baby System

Double Filtration

Two-stage filtration for superior quality output

Moisture Removal

Complete moisture elimination from plastic lumps

Premium Quality

Superior quality granules with consistent size

Mother Baby Plastic Recycling Machine - Superior Double Stage Technology

Mahek Roto Mech introduces the advanced Mother Baby Plastic Recycling Machine, featuring a sophisticated double-stage extrusion process that delivers unparalleled quality in plastic granule production. This innovative system combines two extruders working in tandem to ensure superior output quality with complete moisture removal and double filtration.

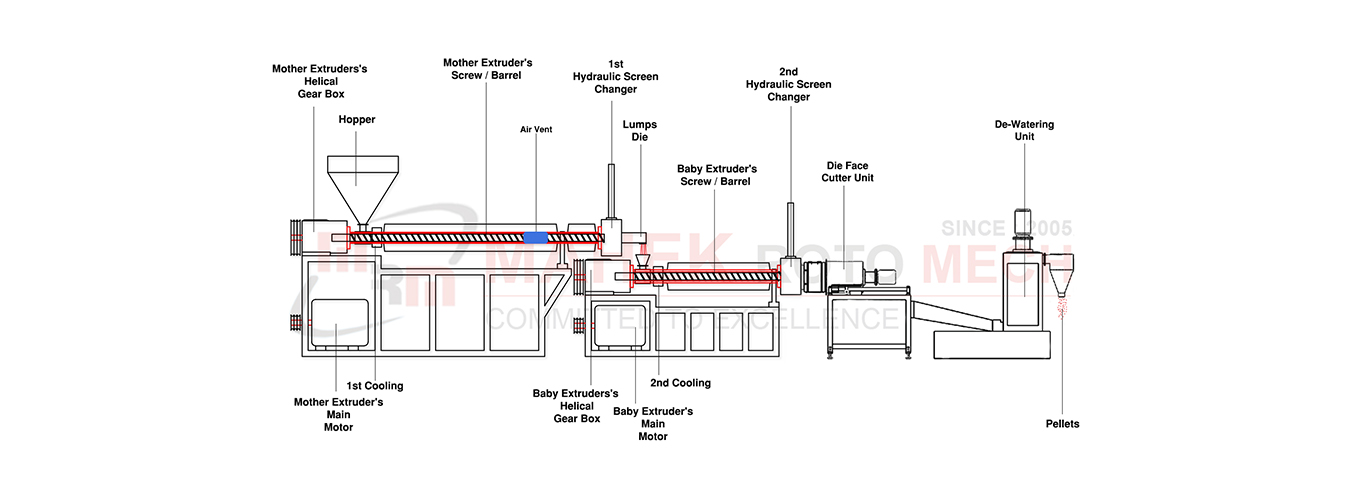

Two-Stage Processing Technology

Stage 1: Mother Extruder

- Primary extrusion and melting process

- Initial filtration through hydraulic screen changer

- Moisture removal through unique die design

- Conversion into plastic lumps

Stage 2: Baby Extruder

- Secondary extrusion for refined processing

- Final filtration through second screen changer

- Conversion into uniform plastic strands

- Pelletizing into finished granules

How Mother Baby System Works

The process begins with plastic flakes entering the mother extruder hopper. A hopper magnet prevents metallic contamination as material feeds onto the rotating screw. The material melts in the heated barrel and undergoes primary filtration through a hydraulic screen changer.

The unique die design converts molten plastic into lumps, effectively removing all possible moisture. These lumps then feed directly into the baby extruder for secondary processing, where they undergo final filtration and conversion into uniform strands before pelletizing into premium quality granules.

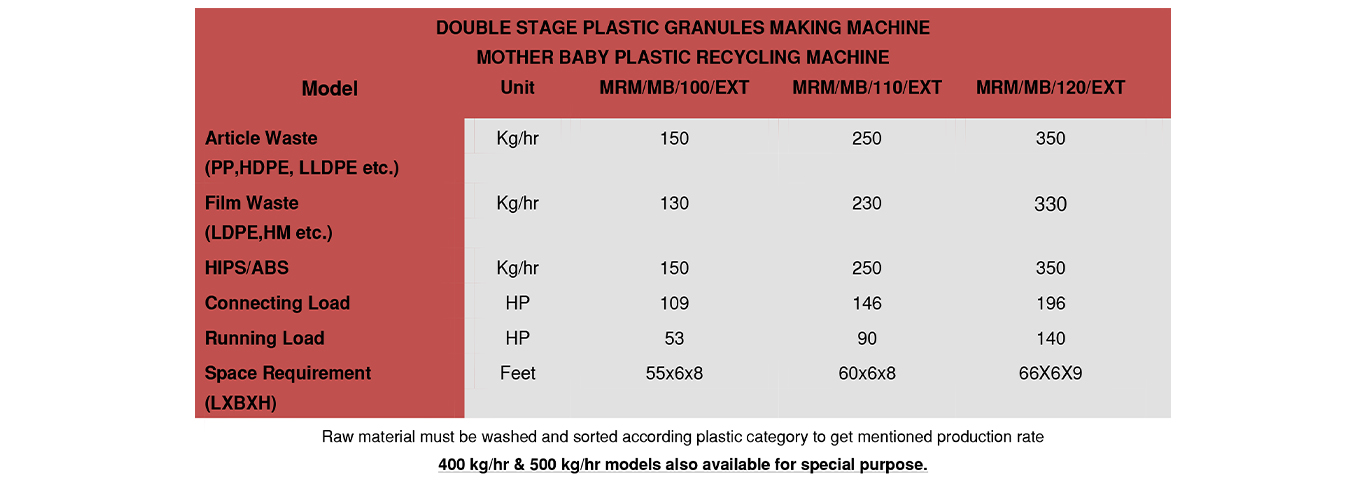

Technical Specifications

| Parameter | Specification |

|---|---|

| Production Capacity | 100 kg/hr to 500 kg/hr |

| Screw Size Range | 90 mm to 130 mm |

| Screw & Barrel Material | EN41-B mild steel, nitride and honing finished |

| Number of Extruders | Two (Mother + Baby) |

| Filtration Stages | Double filtration with hydraulic screen changers |

| Material Compatibility | LLDPE, HDPE, LDPE, PP, HM, ABS, HIPS |

| Drive System | AC motors with heavy duty helical gearboxes |

Salient Features Premium Quality

- Dual extruder system (Mother + Baby) for superior processing

- EN41-B mild steel screws & barrels with nitride finishing

- Optional tungsten carbide coating for extended durability

- Material-specific screw designs for optimal performance

- Multiple heating zones with precise temperature control

- Digital pyrocontrol panel for energy-efficient operation

- Dual hydraulic screen changers for double filtration

- Unique die design for complete moisture removal

- High-efficiency hopper magnets for contamination prevention

- AC motors with heavy-duty helical gearboxes from reputed brands

- Robust MS channel frame construction with CRC sheet covering

- Stainless steel cooling tank with guide rollers

- Pelletizing unit with carbide tip blades for uniform granules

Optional Features Customizable

- Tungsten carbide coated screw & barrel for high RPM operation

- AC drives from reputed brands for precise speed control

- Pressure transducer with buzzer system for screen change alerts

- Accumulator power pack for faster hydraulic operation

- Automatic hopper loader for labor-free material feeding

- Air knife system for moisture-free pellet output

- Forced feeder for low-density material processing

- Barrel vent for engineering grade materials

- PLC based HMI control panel with touch screen interface

- Vibro shifter for automatic rejection separation

Premium Quality Output

Our Mother Baby Recycling Machine produces superior quality granules with:

- Uniform size and shape consistency

- Complete moisture elimination

- Double filtration for purity

- Premium appearance and quality

Machine Layout & Design

Why Choose Mother Baby System Over Single Extruder?

Mother Baby System Advantages

- Superior quality output with double filtration

- Complete moisture removal capability

- Higher production efficiency

- Better material homogenization

- Premium grade granules production

Ideal Applications

- Virgin material processing

- Quality-conscious recycling operations

- Engineering grade plastics

- Premium product manufacturing

- Export-quality granule production

Ready for Premium Quality Plastic Recycling?

Upgrade to our Mother Baby Recycling Machine for superior granule quality and production efficiency